Ladder logic is the main programming method used for

PLCs. As mentioned before, ladder logic has been developed to mimic

relay logic. The decision to use the relay logic diagrams was a

strategic one. By selecting ladder logic as the main programming method,

the amount of retraining needed for engineers and tradespeople was

greatly reduced.

Modern control systems still include relays, but these

are rarely used for logic. A relay is a simple device that uses a

magnetic field to control a switch, as pictured in See Simple Relay

Layouts and Schematics. When a voltage is applied to the input coil, the

resulting current creates a magnetic field. The magnetic field pulls a

metal switch (or reed) towards it and the contacts touch, closing the

switch. The contact that closes when the coil is energized is called

normally open. The normally closed contacts touch when the input coil is

not energized. Relays are normally drawn in schematic form using a

circle to represent the input coil. The output contacts are shown with

two parallel lines. Normally open contacts are shown as two lines, and

will be open (non-conducting) when the input is not energized. Normally

closed contacts are shown with two lines with a diagonal line through

them. When the input coil is not energized the normally closed contacts

will be closed (conducting).

Relays are used to let one power

source close a switch for another (often high current) power source,

while keeping them isolated. An example of a relay in a simple control

application is shown in See A Simple Relay Controller. In this system

the first relay on the left is used as normally closed, and will allow

current to flow until a voltage is applied to the input A. The second

relay is normally open and will not allow current to flow until a

voltage is applied to the input B. If current is flowing through the

first two relays then current will flow through the coil in the third

relay, and close the switch for output C. This circuit would normally be

drawn in the ladder logic form. This can be read logically as C will be

on if A is off and B is on.he first PLCs were programmed with a technique that was based on relay

logic wiring schematics. This eliminated the need to teach the

electricians, technicians and engineers how to program a computer - but,

this method has stuck and it is the most common technique for

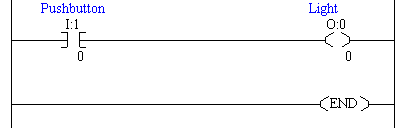

programming PLCs today. An example of ladder logic can be seen in See A

Simple Ladder Logic Diagram. To interpret this diagram imagine that the

power is on the vertical line on the left hand side,

we call this the hot rail. On the right hand side is the neutral rail.

In the figure there are two rungs, and on each rung there are

combinations of inputs (two vertical lines) and outputs (circles). If

the inputs are opened or closed in the right combination the power can

flow from the hot rail, through the inputs, to power the outputs, and

finally to the neutral rail. An input can come from a sensor, switch, or

any other type of sensor. An output will be some device outside the PLC

that is switched on or off, such as lights or motors. In the top rung

the contacts are normally open and normally closed. Which means if input

A is on and input B is off, then power will flow through the output and

activate it. Any other combination of input values will result in the

output X being off.

A Simple Ladder Logic Diagram

The second rung of See A Simple Ladder Logic Diagram is

more complex, there are actually multiple combinations of inputs that

will result in the output Y turning on. On the left most part of the

rung, power could flow through the top if C is off and D is on. Power

could also (and simultaneously) flow through the bottom if both E and F

are true. This would get power half way across the rung, and then if G

or H is true the power will be delivered to output Y. In later chapters

we will examine how to interpret and construct these diagrams.

There are other methods for programming PLCs. One of the

earliest techniques involved mnemonic instructions. These instructions

can be derived directly from the ladder logic diagrams and entered into

the PLC through a simple programming terminal. An example of mnemonics

is shown in See An Example of a Mnemonic Program and Equivalent Ladder

Logic. In this example the instructions are read

one line at a time from top to bottom. The first line 00000 has the

instruction LDN (input load and not) for input A. This will examine the

input to the PLC and if it is off it will remember a 1 (or true), if it

is on it will remember a 0 (or false). The next line uses an LD (input

load) statement to look at the input. If the input is off it remembers a

0, if the input is on it remembers a 1 (note: this is the reverse of

the LD). The AND statement recalls the last two numbers remembered and

if the are both true the result is a 1, otherwise the result is a 0.

This result now replaces the two numbers that were recalled, and there

is only one number remembered. The process is repeated for lines 00003

and 00004, but when these are done there are now three numbers

remembered. The oldest number is from the AND, the newer numbers are

from the two LD instructions. The AND in line 00005 combines the results

from the last LD instructions and now there are two numbers remembered.

The OR instruction takes the two numbers now remaining and if either

one is a 1 the result is a 1, otherwise the result is a 0. This result

replaces the two numbers, and there is now a single number there. The

last instruction is the ST (store output) that will look at the last

value stored and if it is 1, the output will be turned on, if it is 0

the output will be turned off.